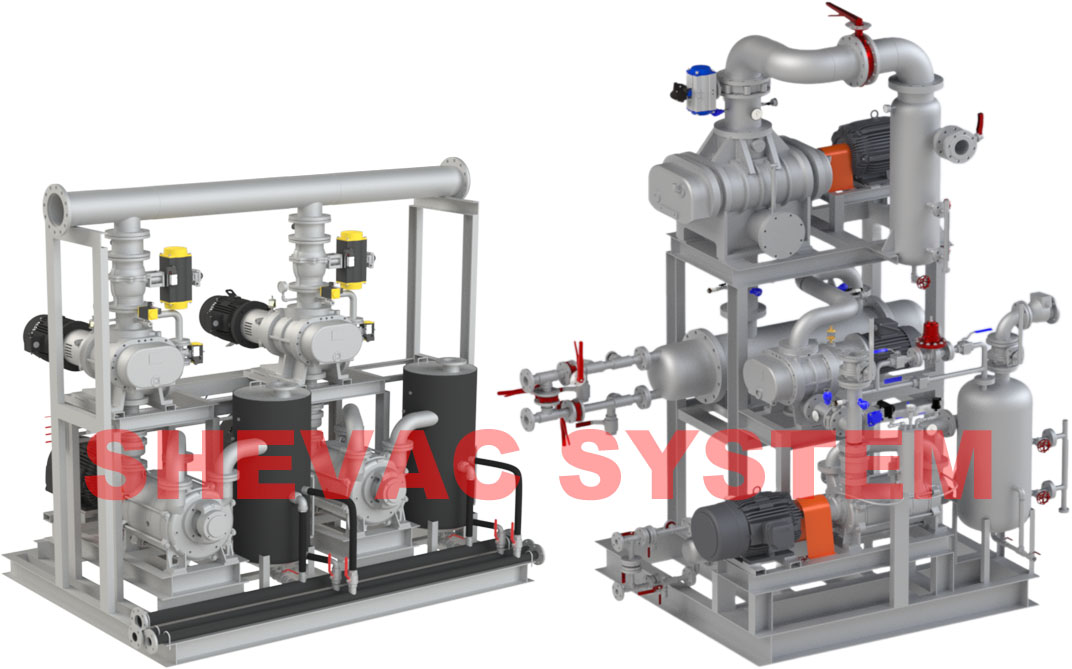

Customized Vacuum Systems

Specification

•Roots pump + liquid seal vacuum pump in duplex combination•Maximum inlet pressure: Atmospheric pressure

•Pumping speed: 5,000~150,000 Liter /min

•Maximum vacuum: Up to 5~5 ×10-3 Torr (depending on different models)

Practical operation vacuum: 110~8 ×10-2 Torr (depending on different models)

•HP: Installed to meet actual requirement of vacuum system

•Air pipe: Standard PU pipe, or optional copper pipe or SUS 304, SUS 316 stainless steel pipe

The vacuum system (liquid ring vacuum pump with

booster pump) takes advantage of the liquid ring (water ring) vacuum pump’s

ability to handle moisture, water vapor and corrosive gases, and combines it

with the large pumping speed and medium-to-high vacuum performance of

Roots-type mechanical booster pumps to provide stable and fast evacuation even

under harsh gas conditions. Such systems are widely used in CCL and PCB

electronics manufacturing, as well as in vacuum distillation, degassing,

dewatering, drying, deodorizing, cooling, concentration, impregnation, vacuum

metallurgy, vacuum casting, vacuum evaporation deposition, sintering, vacuum

insulation, crystallization, optical industry processes, vacuum filling,

solvent recovery, sterilization, packaging, heat treatment, low-temperature

processes, vacuum research and experiments, foam molding and freeze drying.

They are particularly suitable as a versatile reduced-pressure source for wet

processes involving moisture, solid particles and corrosive gases, providing

reliable vacuum extraction for a wide variety of industrial applications.

SMLC系列-液封式真空系統(工作液閉路循環)

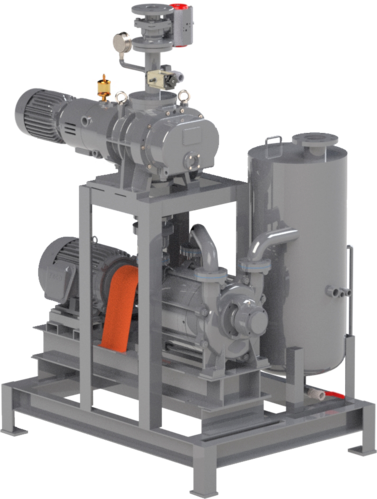

Mechanical booster pumps vacuum pumping systems(SML-1)(760~3.75Torr)

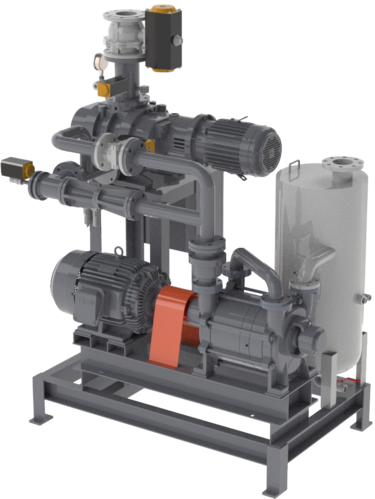

Mechanical booster pumps vacuum pumping systems(SML-2)(760~0.2Torr)

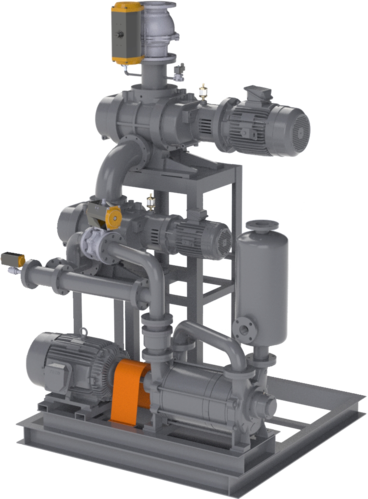

Mechanical booster pumps vacuum pumping systems(SML-3) (760~0.02Torr)

The system is equipped with essential control components such as vacuum gauges, vacuum switches, relief valves, and pneumatic vacuum valves, offering advantages including high ultimate vacuum, high reliability, reduced evacuation time,...

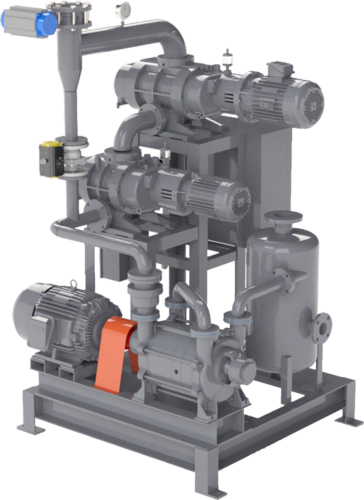

Mechanical booster pumps vacuum pumping systems(SML-4)(760~0.2Torr)

The system is equipped with key control components such as vacuum gauges, vacuum switches, relief valves, and pneumatic vacuum valves, offering advantages including high ultimate vacuum, high reliability, reduced evacuation time, energy savings, lower equ...