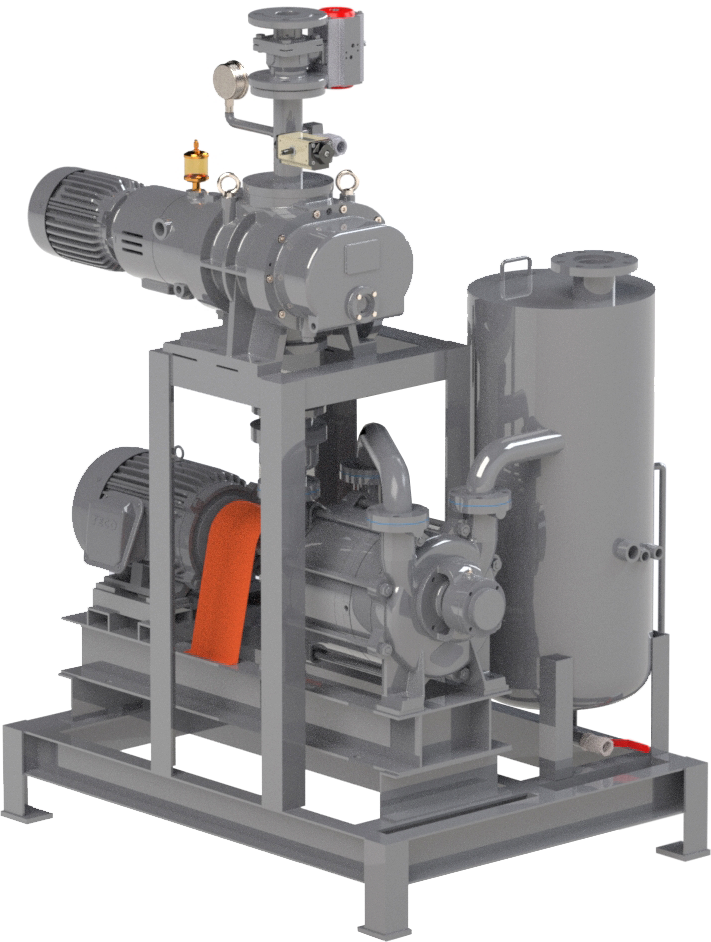

What is a vacuum pumping system

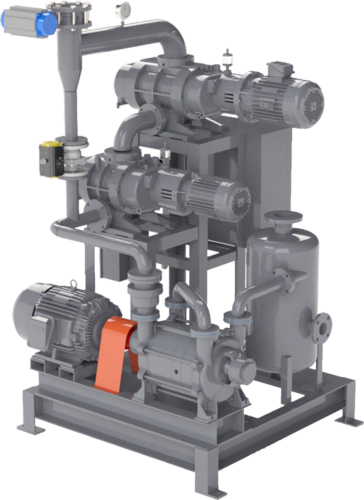

A vacuum pumping system is usually

composed of two main parts:

-

Fore‑vacuum pump: For example, an oil‑sealed rotary vane pump or a liquid ring vacuum pump, which starts

pumping from atmospheric pressure and can discharge the gas directly to

atmosphere.

-

Mechanical vacuum booster pump (such

as a Roots pump): This pump provides very high pumping speed in the medium to

high vacuum range, but it cannot compress and discharge gas directly to

atmosphere and therefore needs to work together with a fore‑vacuum pump.

Why combine them into a system

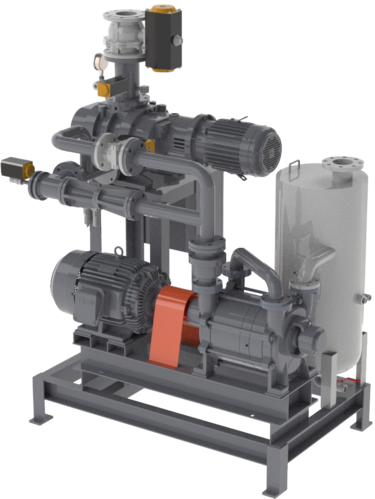

A mechanical vacuum booster pump is

very efficient and offers large pumping speed in the medium to high vacuum

range, but it cannot exhaust directly to atmosphere.

-

Oil‑sealed rotary vane pumps and liquid ring pumps can exhaust directly to

atmosphere, but their efficiency is relatively low in the medium to high vacuum

range.

-

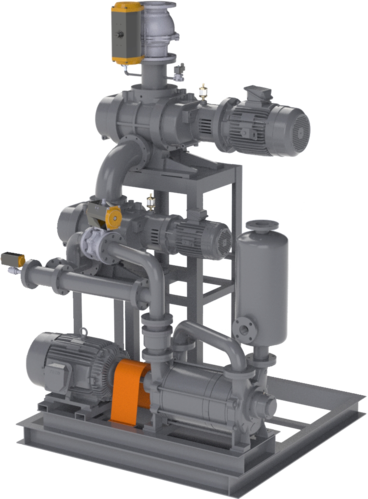

By combining the two (booster pump +

fore‑vacuum pump), the system can both

discharge to atmosphere and maintain high pumping speed in the medium to high

vacuum range, significantly increasing the overall exhaust rate and improving

the achievable vacuum level.

Automation and operation

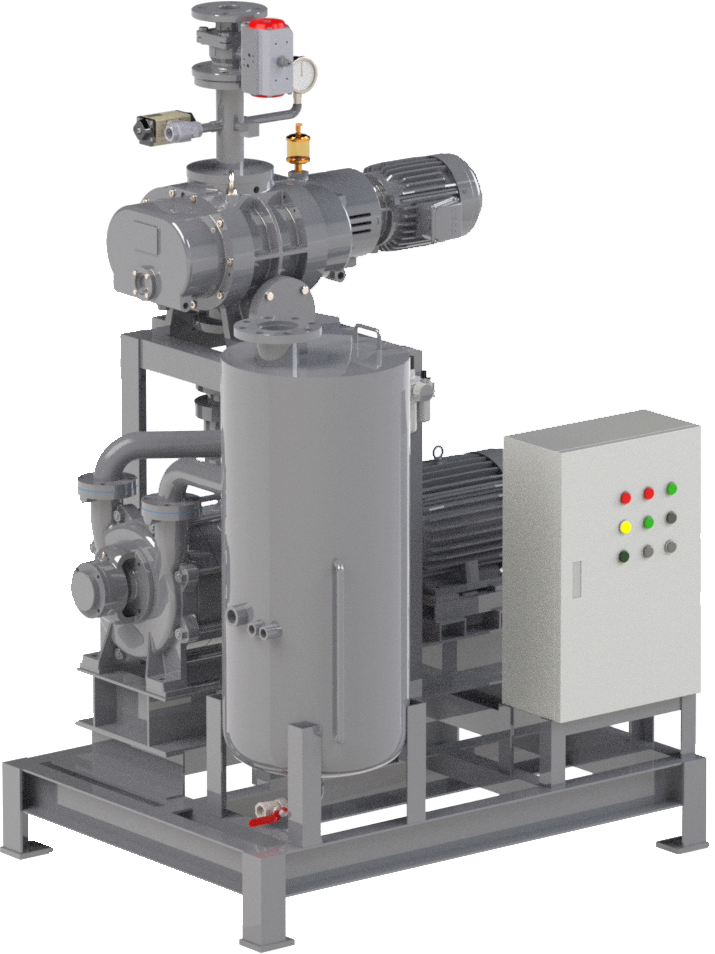

A complete vacuum exhaust system is

further equipped with instruments such as a vacuum gauge, vacuum switch, relief

valve, pneumatic vacuum valves, and other control components.Through control logic, the system

automatically determines when to start or stop the booster pump, so the

operator only needs to operate the main unit or control panel, without manually

calculating or judging the proper timing and procedure for starting the

mechanical booster pump, thus achieving stable and simplified automated

operation.

FORMANCE RANGES OF MECHANICAL BOOSTER VACUUM PUMP

|

型 式 Model |

排氣速度 Capacity m³/h |

最 終 壓 力 Ultimate Press.Torr |

後 段 幫 浦 Backing Pumps |

總 馬 力 Total Power HP |

口 徑 mm(in) |

|

|

Inlet |

Outlet |

|||||

|

SMB65 |

300 |

2(0.2) |

SWV-5D |

2 + 5 |

65 (2.5) |

50(2) |

|

0.2 |

SOV-5DW |

2+5 |

50(2) |

|||

|

SMB80 |

500 |

2(0.2) |

SWV-7D |

3 + 7.5 |

80 (3) |

50(2) |

|

0.2 |

SOV-5DW |

3+5 |

50(2) |

|||

|

SMB100 |

700 |

2(0.2) |

SWV-10D |

5 + 10 |

100 (4) |

50(2) |

|

0.2 |

SOV-5DW |

5+5 |

50(2) |

|||

|

0.1(0.01) |

SMB65+SWV-5D |

5+3+5 |

50(2) |

|||

|

SMB125A |

1000 |

2(0.2) |

SWV-15 |

7.5 + 15 |

125 (5) |

50(2) |

|

0.2 |

SOV-7DW |

7.5+7.5 |

50(2) |

|||

|

0.1(0.01) |

SMB80+SWV-7D |

7.5+3+7.5 |

50(2) |

|||

|

SMB125 |

1500 |

2(0.2) |

SWV-20 |

10 + 20 |

125 (5) |

50(2) |

|

0.2 |

SOV-10DW |

7.5+10 |

50(2) |

|||

|

0.1(0.01) |

SMB100+SWV-15 |

7.5+5+15 |

50(2) |

|||

|

SMB150 |

2000 |

2(0.2) |

SWV-700 |

15 + 40 |

150 (6) |

80(3) |

|

0.2 |

SOV-20DW |

10+20 |

50(2) |

|||

|

0.1(0.01) |

SMB125A+SWV-20 |

10+7.5+20 |

50(2) |

|||

|

SMB200A |

3200 |

0.1(0.01) |

SMB125A+SWV-600 |

15+7.5+30 |

200 (8) |

80(3) |

|

0.2 |

SOV-700W |

15+40 |

80(3) |

|||

|

SMB200 |

4100 |

0.1(0.01) |

SMB125+SWV-700 |

20+10+40 |

200 (8) |

80(3) |

|

0.2 |

SOV-900W |

20+40 |

100(4) |

|||

|

SMB250 |

5400 |

0.1(0.01) |

SMB150+SWV-900 |

25+10+40 |

250 (10) |

100(4) |

|

0.2 |

SOV-900W |

20+50 |

100(4) |

|||

|

SMB300A |

7500 |

0.2 |

SOV-1300W |

30+50 |

300(12) |

100(4) |

|

SMB300 |

9000 |

0.2 |

SOV-1300W |

30+60 |

300(12) |

100(4) |

Wide applicable pressure range:

By sharing the workload between the fore‑vacuum pump and the mechanical booster pump, the usable range extends from rough vacuum to medium and high vacuum, and an atmospheric booster can be optionally added to further improve the ultimate pressure.

High pumping speed and reduced evacuation time:

In the medium to high vacuum range, the mechanical booster pump provides a high exhaust rate, significantly shortening the time required to reach the working vacuum from atmosphere and increasing equipment throughput.

Easy automation and operation:

The system integrates a vacuum gauge, vacuum switch, pneumatic vacuum valves, and protection logic, enabling automatic start and stop of the booster pump according to the pressure range, so the operator does not need to judge the timing manually.

Energy saving and cost reduction:

Using the most suitable pump in each pressure range reduces unnecessary energy consumption, and compared with a single large‑pump solution, offers both lower capital cost and lower operating cost.

Modular design and customization flexibility:

Depending on the actual process requirements, different pumping speeds, ultimate pressures, and fore‑pump types (liquid ring or oil‑sealed rotary vane) can be selected, and the system can be expanded with multiple units in parallel or with an atmospheric booster to meet higher pumping speed or lower pressure demands.